Simple and fast analysis of beer quality directly where you need it.

|

Regardless of scale, the brewing process is basically the same. Malted grains are milled and put into a vessel where they are held at a warm temperature to allow the enzymes to break down the complex carbohydrates into fermentable sugars. This mash is transferred and the sweet liquid, called wort, is separated from the spent grains. Hops are added and the wort is boiled to sterilize it. Next it is cooled and aerated. Yeast is added for fermentation, producing carbon dioxide, alcohol, aromas, and flavors. After fermentation the beer is transferred into a tank for maturation. The yeast is allowed to flocculate and settle out, clarifying the beer and physically stabilizing it. The average strength of beer is between 4.8% and 5.2% alcohol by volume (ABV). The range of strength is however far wider than that of wine. There are many beers on the market with only 3.5% ABV or below, whereas some beer styles, such as barley wine or imperial stouts, commonly reach 12% ABV. |

|

To guarantee a high and reproducible quality of beer and to comply with the enhanced expectations of the consumers, the brewery industry applies a variety of analytical methods for beer quality control. Distillation, densimetry, refractometry, high-performance liquid chromatography, gas chromatography, enzymatic analysis and spectrophotometry are used for the assessment of important physicochemical parameters such as alcoholic strength, relative density, original gravity, fermentable and non-fermentable sugars, lactic acid concentration, pH, bitterness and colour. Trends in food analysis are towards fast, simple and reliable analytical techniques with the potential to partly or fully replace the complex and expensive reference methods. |

||

| This fits perfectly with the philosophy of SWIRL.vision who have recently developed a beer analyzer that requires no sample preparation whatsoever, and delivers consistent results with relatively little care and expertise, within a couple of minutes. The core is a robust Fourier-transform infrared spectroscopy (FTIR) instrument combined with leading edge Machine Learning algorithms. This not only delivers unprecedented precision in Alcohol and Original Extract analysis but in that same run provides sugar content, CO2, foreign gas and pH without any sample prep. Notably the power of FTIR to distinguish between types of sugars is exploited, enabling an accurate measurement of the remaining fermentable as well as non-fermentable sugars. Eliminating sample preparation, short analysis time and low equipment maintenance will guarantee a fast Return on Investment. |  |

|

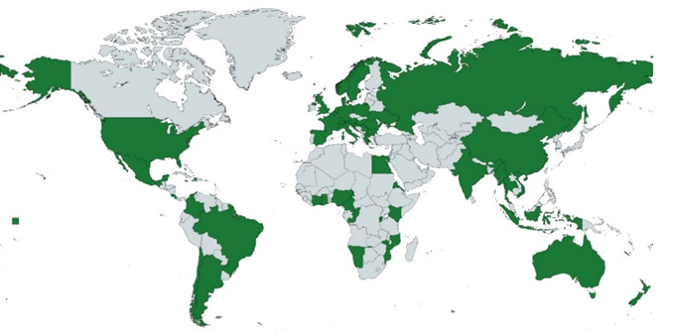

| Brewers use a wide variety of ingredients to achieve the aroma, body, flavor and finish they desire in their beer. The world map provides an indication (in green) on the training base of the algorithm to ensure robustness against a wealth of interferences. Month by month this base grows bigger and the algorithm stronger. At the same time it allows expanding the number of analytes the technology will offer. | ||

|

||